Controlling the stiffness of a silicone part: why design matters more than hardness

In industrial and food-processing applications, silicone parts are often selected for their flexibility, durability, and compatibility with demanding environments.

When it comes to cleaning, contact, or wiping functions, one requirement frequently arises: achieving a part that is both flexible and stable, capable of operating consistently over time.

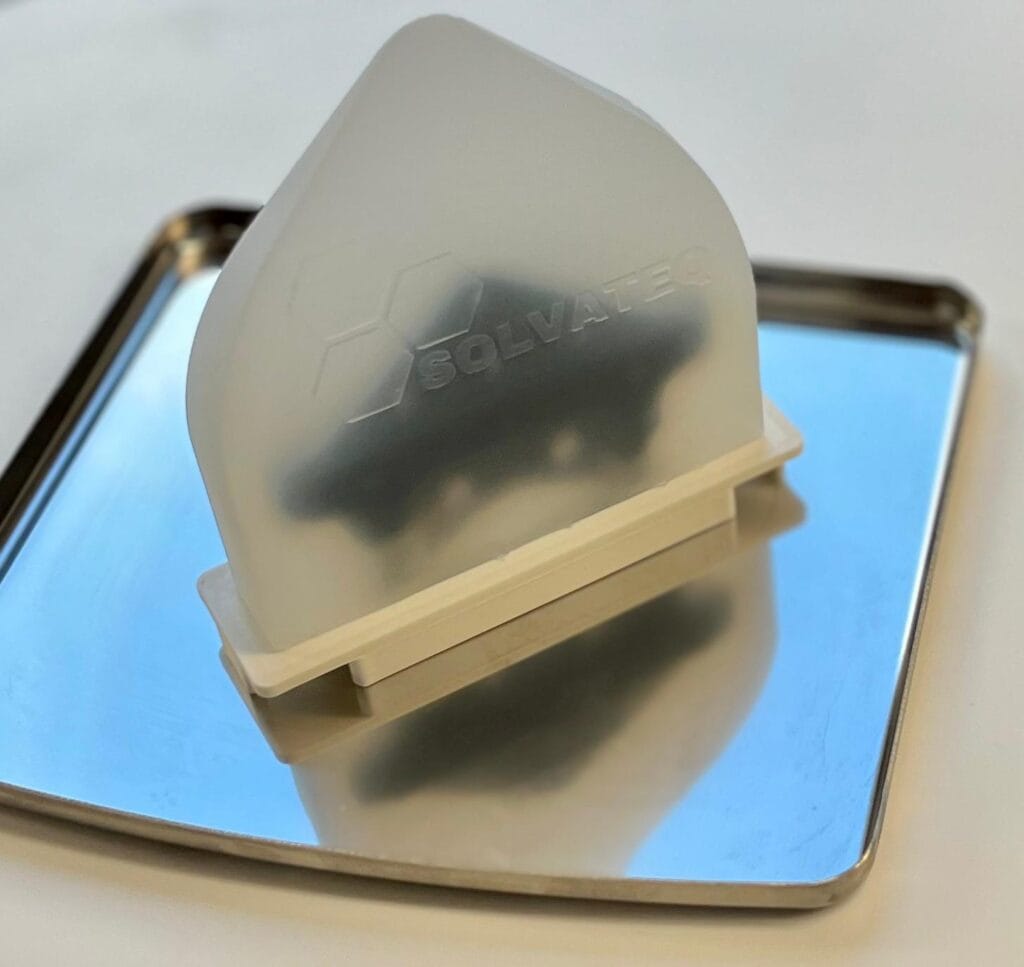

This conveyor scraper project illustrates a key point that is often underestimated:

👉 the stiffness of a silicone part is primarily controlled through design, not solely through material hardness.

A clear functional requirement in a constrained environment

The scraper had to ensure continuous cleaning of a conveyor operating in a cold and humid environment, with a geometry imposed by the conveyor’s alveolar structure.

The part needed to:

conform to the surface to be cleaned,

efficiently evacuate residues,

remain stable during operation,

and be fixed and replaced despite limited access.

A standard solution, or a fully flexible part with uniform thickness, could not sustainably meet all of these constraints.

A common misconception about flexible parts

When faced with this type of challenge, the first instinct is often to adjust the silicone hardness: harder for better support, softer to better follow the shape.

In practice, this approach quickly shows its limitations:

if too soft, the part folds, floats, or collapses under load,

if too stiff, uniform contact can no longer be ensured,

and the fixation becomes unstable or difficult to maintain over time.

The issue therefore did not stem from the material itself, but from the mechanical architecture of the part.

Separating functions to control behavior

After several trials and observations under conditions close to real use, the solution was to clearly separate the functions within the part.

The selected approach relies on:

integrating a rigid element to ensure geometric stability along the length of the part and provide reliable fixation,

combined with a local variation in silicone thickness, preserving the necessary flexibility in the contact area.

This design makes it possible to control stiffness where it is needed, without compromising the primary cleaning function.

More stable and reproducible behavior

This combination resulted in improved positional stability of the scraper, with consistent behavior over time, regardless of load variations or environmental conditions.

It is worth noting that the cold and humid environment did not impose any specific limitation on the material itself: the selected silicone was well within its operating range.

The initial difficulties were therefore clearly related to the design, not to a material limitation.

What this project demonstrates

This concrete case highlights a fundamental principle in the development of functional silicone parts:

Stiffness is not chosen solely from a material datasheet.

It is designed, distributed, and structured.For prototyping and small-series projects, this approach makes it possible to:

avoid unnecessary iterations,

secure performance under real operating conditions,

and achieve solutions that are both technically and economically coherent.

Do you have a project that requires a functional silicone solution?

Solvateq supports you in the design and manufacture of silicone molds and parts for prototyping and small-series production, with a clearly defined technical scope and well-defined deliverables.