A simple guide to clearly define your technical requirements

At Solvateq, we receive all kinds of requests: sketches drawn on the back of a napkin, advanced 3D models, or ideas explained verbally. That’s perfectly normal—not everyone is an engineer.

But one thing is certain: the better a project is prepared, the faster, more cost-effective, and more successful it will be.

In this article, we share the key steps to prepare your manufacturing project, even if you have no technical background

1. Clarify the Functional Requirement

Before talking about materials, dimensions, or 3D files, ask yourself one simple question:

👉 What will this part be used for?

Its intended use determines everything else:

Mechanical strength (Will it be under load or stress?)

Required precision (Does it fit with other components?)

Aesthetic considerations (Will it be visible to customers?)

Material suitability (Does it need to resist heat, moisture, or chemicals?)

Example: If you request “a plastic bracket,” we will always ask: a bracket for what? Under which conditions?

2. List Known Technical Constraints

Even if you don’t have every detail, the more information you can provide upfront, the better.

Useful details include:

Key dimensions or maximum footprint

Preferred or excluded materials (plastic, metal, flexible, rigid, etc.)

Required resistance (load, temperature, environment)

Assembly tolerances if it must fit with other parts

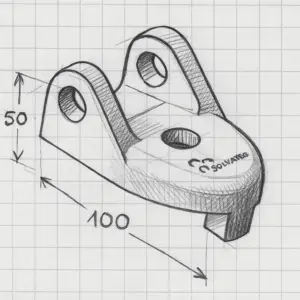

A complete technical file is not required—a hand sketch with measurements is often enough to get started

3. Share Whatever You Have (Even Basic Information)

Do you have a drawing, a 3D model, or just an existing part to replicate or improve? Great.

If you only have an idea, we can help with 3D modeling or refining your concept into a manufacturable design.

Accepted formats: .STL, .STEP, .DXF, PDF, photo with measurements, or a physical part to scan or study.

4. Provide the Overall Project Context

This is often overlooked—but it can make a big difference.

Key context to share:

Quantity needed (prototype, small batch, or large-scale production?)

Timeline (Is it urgent? Any fixed deadlines?)

Indicative budget (if known—it helps us select the most cost-efficient approach)

Example: A one-off functional prototype will be handled differently than a production run of 500 units intended for sale.

✅ The Solvateq Pre-Project Checklist

Before contacting us, try to answer these:

☐ What is the part’s function?

☐ What technical constraints must be met?

☐ Do I have a drawing, plan, or 3D model?

☐ How many units do I need, and by when?

☐ Do I have a maximum budget in mind?

Even partial answers help us get started. If something is missing, we’ll work with you to fill in the gaps

🤝 Have a Project in Mind? Let’s Talk.

At Solvateq, we turn ideas into tangible, high-quality parts—even if you’re starting from scratch. A short conversation is often enough to move forward, define the real need, or avoid costly mistakes.