FROM WEAK LINK TO RELIABLE PERFORMANCE: HOW WE REDESIGNED A CRITICAL COMPONENT FOR THE BUILDING INDUSTRY

When a client in the building services sector approached us, they faced a recurring and costly problem. A key component in their portable pipe-cleaning machines was poorly designed, causing frequent breakages. The downtime and replacement costs were adding up quickly — they needed a lasting solution.

Project overview:

Industry: Building maintenance & pipe cleaning services

Challenge: Frequent breakage of a critical machine adapter

Objective: Redesign and manufacture a more durable part without altering the machine’s overall functionality

Our approach:

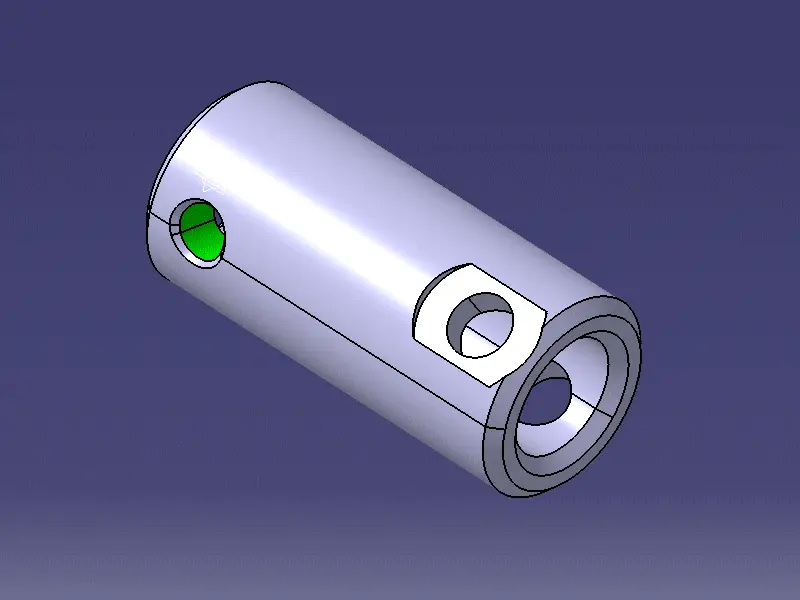

Mechanical design (CAD): We reverse-engineered the broken part, rethinking its geometry to withstand operational stress.

Prototyping: We produced a first prototype in FDM for rapid validation.

Production: Once approved, we machined the parts from durable materials and assembled all components for series production.

Results:

The upgraded part not only eliminated the recurring breakage problem but also delivered substantial cost savings to the client by reducing replacements and downtime