SILICONE EXPERTISE FOR PROTOTYPING AND SMALL-SERIES PRODUCTION

Solvateq supports companies that need reliable silicone solutions for technical, food-grade, and industrial applications. Our expertise focuses on the design and manufacture of silicone molds and parts when standard solutions no longer meet requirements in terms of use, precision, or volume.

Based in Switzerland, the company operates in French-speaking Switzerland and across the country on prototyping, pre-series, and small-series projects.

A CLEAR SPECIALIZATION

Rather than multiplying processes and materials, Solvateq has chosen a focused expertise in silicone. This specialization ensures better control of material properties, usage constraints, and the quality requirements specific to flexible components.

OUR SILICONE SOLUTIONS

SILICONE MOLDS

Design and manufacture of silicone molds for low- and medium-volume production, tailored to prototyping and small-series needs.

Examples:

Molds for chocolate, pastry, and confectionery

Molds for candles and cosmetic parts

Molds for flexible-part prototypes

Molds for small industrial production runs

SILICONE PARTS

Manufacture of silicone parts intended for real-world functions, when the flexibility of the material is a decisive functional advantage.

Examples:

Seals and sealing components

Protective parts and dampers

Covers and ergonomic interfaces

Light diffusers and flexible components

Food-grade silicone parts

COMPLETE SILICONE SOLUTIONS

Comprehensive support for projects requiring a single point of contact, from needs definition to final validation.

Examples:

Development of a silicone part and its mold

Adapting an existing part into a silicone version

Development of a functional prototype

Launch of a small production run ready for manufacturing

WHAT WE DO - AND WHAT WE DON’T DO

To ensure a high level of quality and consistency, Solvateq focuses on targeted projects.

WE WORK ON:

Functional silicone prototypes

Pre-series and small-series production

Silicone molds for in-house production

Projects requiring flexibility and responsiveness

WE ARE NOT POSITIONED FOR:

Mass production

Heavy industrial tooling

Multi-material processes outside of silicone

HOW WE WORK

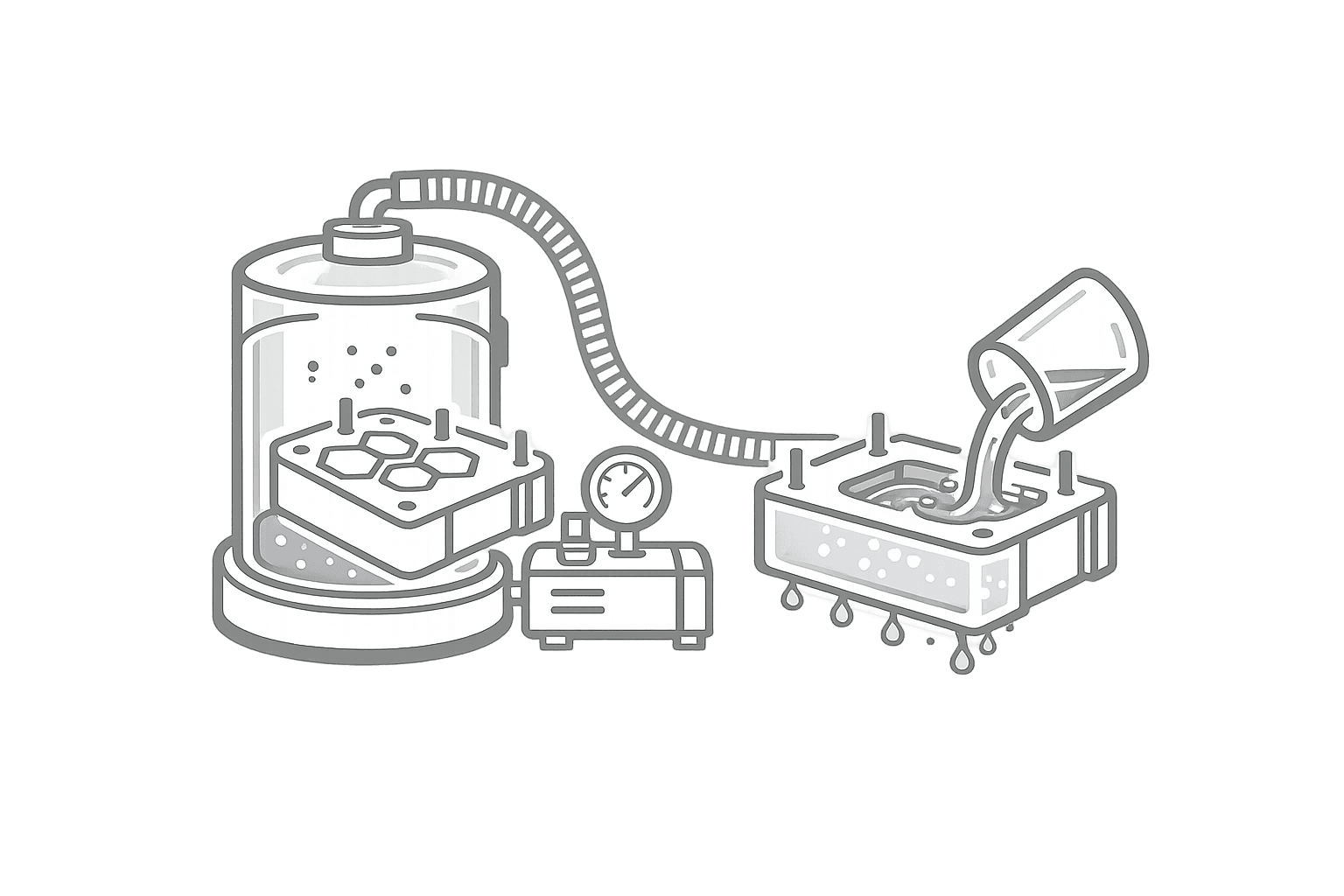

We move forward step by step to ensure functional silicone parts adapted to real-world use. After validating your needs, we define the material solution, design the mold, and manufacture your parts for product validation, pre-series, and small-series production.

1. NEEDS ANALYSIS

Understanding real-world use, technical constraints, and project objectives.

2. DEFINITION OF THE SILICONE SOLUTION

Selection of the silicone type, design of the geometry, and definition of the expected performance level.

3. DESIGN AND MANUFACTURING

Creation of models, mold manufacturing, and production of the first parts.

4. VALIDATION AND ADJUSTMENTS

Functional testing, adjustments if necessary, and preparation for production.

WHY CHOOSE SOLVATEQ FOR YOUR SILICONE PROJECTS?

A COMMITTED SPECIALIZATION

Focused expertise ensures stronger technical control and overall consistency of the proposed solutions.

A USE-ORIENTED APPROACH

Each solution is designed based on its real context of use, not only on its technical feasibility.

EXPERTISE IN SMALL-SERIES PRODUCTION

Prototyping and small-series projects require a flexible and responsive approach.

A SINGLE TECHNICAL POINT OF CONTACT

One point of contact to simplify communication and secure decision-making.

READY TO LAUNCH YOUR SILICONE PROJECT?

From functional analysis to manufacturing, Solvateq supports you in developing silicone solutions tailored to your usage constraints, from prototype to small-series production.