Design, modeling and food-grade silicone molding, custom mold manufacturing in Switzerland

At Solvateq, we design and manufacture custom food-grade silicone molds, for example for chocolate production.

Our specialty: the complete design of “sock” molds — from 3D modeling to final silicone casting — for both food and industrial applications.

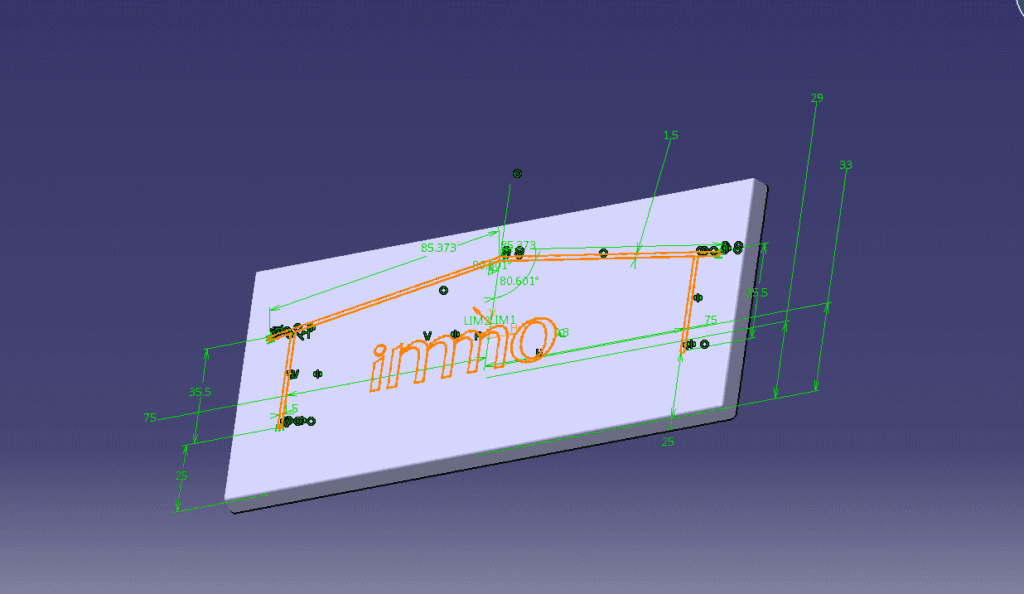

Step 1: Design and 3D modeling

Everything starts with the 3D modeling of the piece to be reproduced.

Our computer-aided design tools allow us to create a precise model that matches the requested final product’s shape and texture.

We then design the outer mold block, optimized to:

- ensure a consistent silicone thickness;

- facilitate demolding;

- guarantee uniform mechanical strength.

This stage is essential to achieve accurate casting and maximize the mold’s lifespan.

Step 2: 3D printing of the mold frame and matrix

Once the design is validated, we 3D print the mold frame (or outer block) as well as the matrix.

This fast and cost-effective solution provides a rigid and precise structure to contain the silicone during casting.

3D printing offers several advantages:

Reduced manufacturing time;

Easy adaptation to any geometry;

Controlled cost, even for small production runs.

Step 3: Casting of food-grade silicone

We use only professional-grade food-safe silicone, compliant with European food contact standards.

Each mold is hand-cast in its 3D-printed frame, then demolded and inspected after curing.

The result: a flexible, precise, and durable mold — perfectly suited for producing items made of chocolate, sugar, marzipan, resin, wax, or plaster.

Custom manufacturing and small-scale production

Solvateq offers the creation of custom molds, either as single units or in small series, according to your needs.

We support professionals in the food, chocolate, design, and industrial sectors through every stage of the process:

Analysis of the model to be reproduced

3D mold design

Printing and casting

Delivery of a ready-to-use mold

Each mold is designed, manufactured, and tested in Switzerland, ensuring artisanal quality with industrial precision.

Why choose Solvateq?

✅ Expertise in mechanical design and 3D modeling

✅ Custom manufacturing in Switzerland

✅ Use of certified food-grade silicone

✅ Fast turnaround and quotes within 48 hours

✅ Professional results at competitive prices

Common applications

Molds for chocolate figurines or pastry decorations

Reproduction of decorative objects in resin or plaster

Production of prototype parts using silicone molding

Creation of flexible “sock” molds for small-scale artisanal production

📞 Contact us

Would you like to design a custom food-grade silicone mold?

Contact Solvateq for a fast, free quote.

We support you through the entire process — from design, modeling, and printing to final manufacturing — from prototype to small-scale production.