⚡ FDM 3D Printing: Quickly Validate Your Mechanical Designs

🎯 The Challenge in Mechanical Design

In product or machine development, 3D design alone is not always enough.

A model may look perfect on screen, but once brought into reality, problems often arise:

A dimension too tight or too loose,

A hole incorrectly positioned,

A part that doesn’t fit properly into its environment,

A shape that is awkward or uncomfortable to handle.

👉 Until the part has been physically tested, there is always a risk.

Traditionally, validation is done with machining, but this involves:

several days (or even weeks) of waiting,

very high costs,

and above all, difficulties in carrying out multiple quick iterations.

🖨️ FDM 3D Printing as a Rapid Prototyping Solution

FDM 3D printing (Fused Deposition Modeling) makes it possible to directly transform a 3D model into a physical part in just a few hours.

Key advantages for prototyping:

Speed: a prototype available in 2–6 hours instead of several days,

Cost efficiency: no tooling required, affordable materials,

Flexibility: ability to modify the file and reprint immediately,

Real validation: dimensions, positions, ergonomics, and assemblies tested directly.

⚡ From Idea to Test in 24 Hours

With FDM 3D printing, it is possible to complete a full cycle:

CAD design,

Prototype printed in a few hours,

Immediate physical testing,

Corrections and reprinting if necessary.

👉 This iterative process allows much faster progress, with controlled costs.

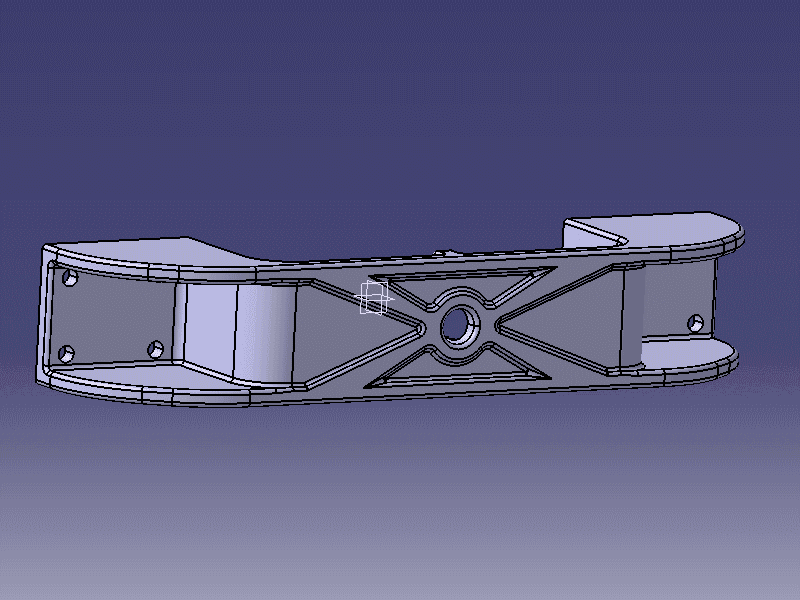

💡 Practical Example – Pantograph Supports

At Solvateq, we needed to test the integration of pantograph supports for a machine.

Traditional method: machining would have required several days of waiting, and each correction would have generated significant additional costs and delays.

FDM 3D printing: the first prototype was printed in 3 hours, tested immediately, corrected, and reprinted shortly after. Once validated, the part could be sent for machining with full confidence.

👉 Result: several iterations carried out in just a few days, rapid validation of dimensions and positions, and costs reduced to a fraction of direct machining.

✅ Conclusion: Saving Time and Money

Rapid prototyping with FDM 3D printing has become essential to secure and accelerate mechanical development:

Reduced lead times,

Validation of dimensions, positions, and shapes,

Easier iterations,

Development costs significantly reduced.

At Solvateq, we systematically integrate FDM 3D printing into our design and prototyping processes to turn your ideas into tangible, testable, and validated prototypes in record time.